Gleisschrauben Schrauben Muttern Unterlegscheiben Sechskant

$0.19≥10000Piece/Pieces

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 10000 Piece/Pieces |

| Transport: | Ocean,Land,Air |

| Hafen: | NINGBO |

$0.19≥10000Piece/Pieces

| Zahlungsart: | T/T,L/C,D/P |

| Incoterm: | FOB,CFR,CIF,EXW |

| Minimum der Bestellmenge: | 10000 Piece/Pieces |

| Transport: | Ocean,Land,Air |

| Hafen: | NINGBO |

Marke: KST

| Verkaufseinheiten | : | Piece/Pieces |

| Pakettyp | : | luftblasenbeutel kartons |

The file is encrypted. Please fill in the following information to continue accessing it

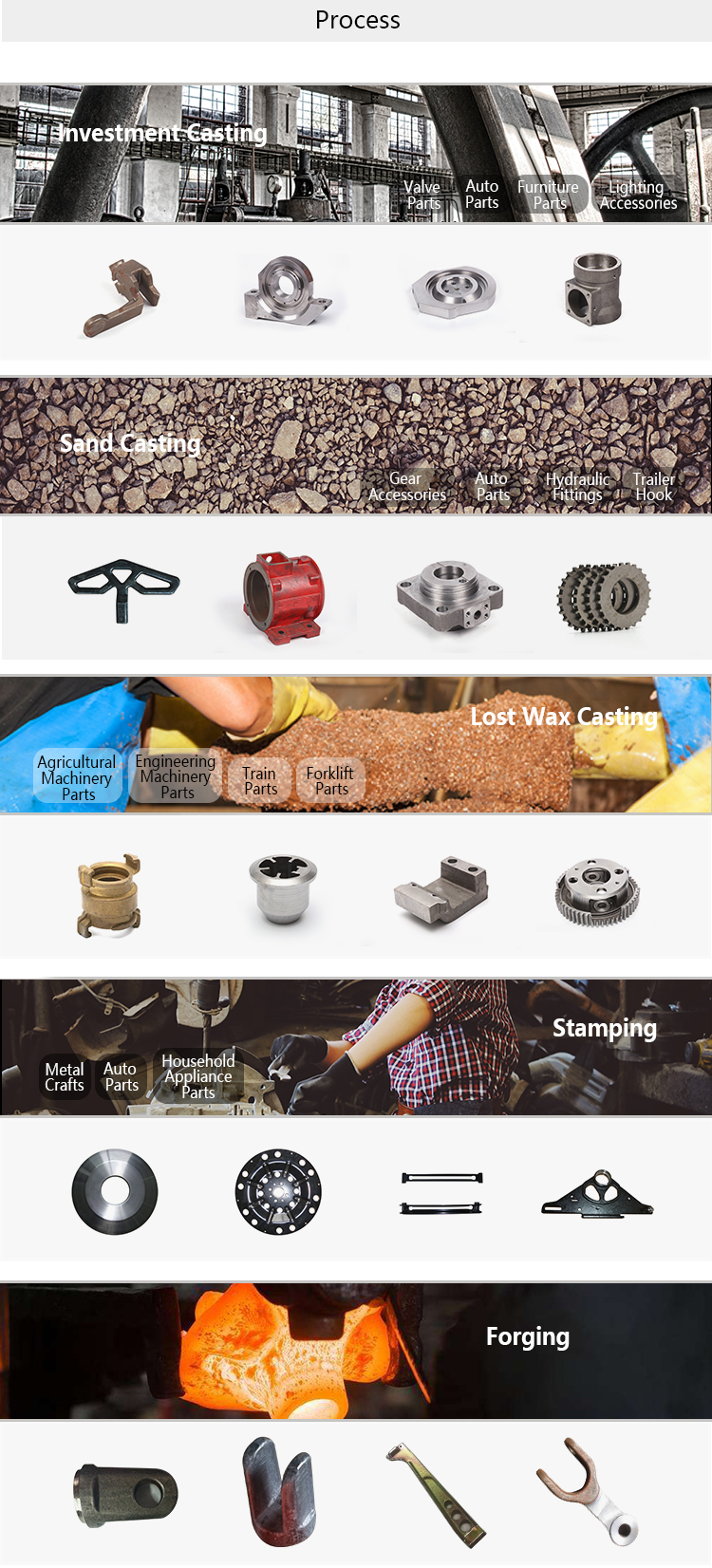

OEM maßgeschneiderte Feingussteile aus Edelstahl 316 Spurschrauben Schrauben und Muttern und Unterlegscheiben Sechskantkopf

CNC-Bearbeitungsteile

Wir sind OEM & ODM. Wir haben unsere eigene Forschungs- und Entwicklungsabteilung, wir können die Teile nach Kundenwunsch herstellen.

Unsere Teile sind weit verbreitet in Autoteilen (wie Radnabe, Anhängerkupplung,

Luftfederunterstützung für Autoteile, Abschlepphaken usw.); Ventilgussteile, Ventilarmaturen, Landmaschinenteile, Pumpen etc.

Welche Arten von Produkten können wir anbieten?

| Products | According to the customers'technical drawings or s amples | |||||

| Casting Material | Cast Iron, ductile iron, Grey iron, GG25, GG20, GGG40, GGG50, GGG60 GGG70: | |||||

| QT400-18,QT450-10,0T600-3QT700-2,FCD400,FCD450,60-40-18,65-45-12,ect. | ||||||

| Casting Product Weight | available from 0.02kg to 3000kg | |||||

| Surface Treatment | Oxidation | |||||

| Plating zinc | ||||||

| Painting | ||||||

| Hot galvanized | ||||||

| Powder coating | ||||||

| Electroplating | ||||||

| Sand blasting | ||||||

| Electrophoresis | ||||||

| Vbration Grinding | ||||||

| Inspection | *100% ins pection before shipping, offer the material reports and mechanical property reports | |||||

| *Control Plan and PPAP documents according to the clients'requirements | ||||||

| *ISO9001: 2015 quality control system | ||||||

| Extra Service | CNC machining servce in our machining workshop | |||||

| Advantages | * The dimensions and outs ide shape are similar with investment casting | |||||

| *The surface roughness is good from 2.5 to 25um(100 to 1000um | ||||||

| *The min thickness can meet 3 mm(0. 120inch) | ||||||

| *decrease the internal crack and keep close structure | ||||||

| *As no joint and defect the cleaning and machining work can be less | ||||||

| *it's cheaper because its a simpler process and the foam is cheaper than the wax | ||||||

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.